Last Edited:

Jun 24, 2024

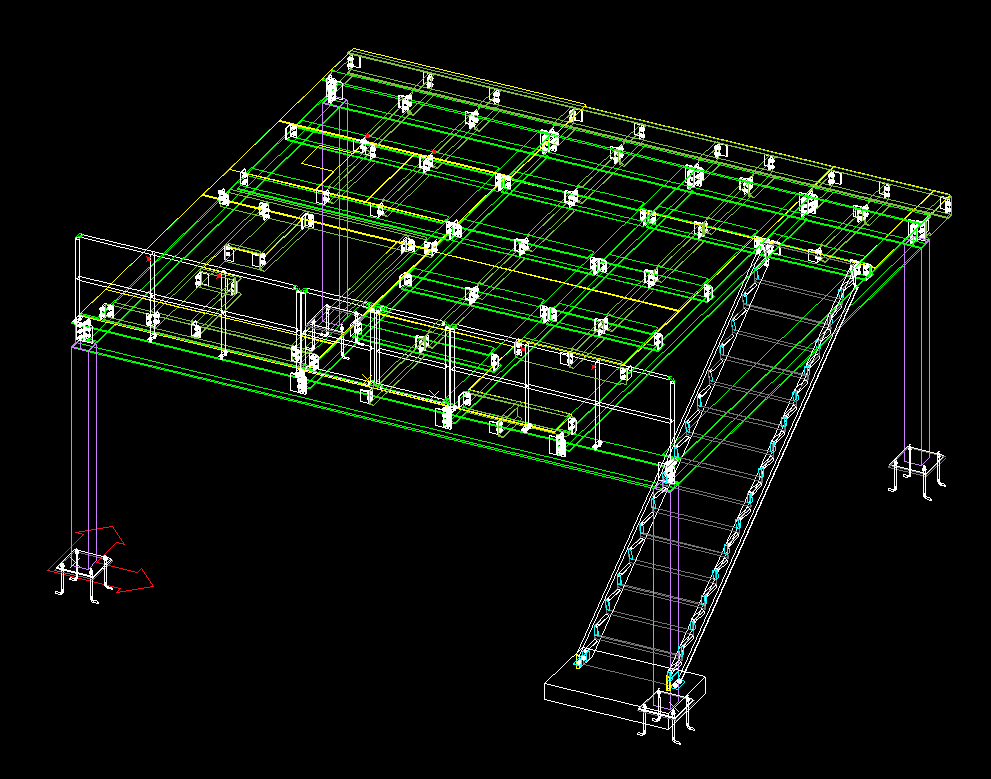

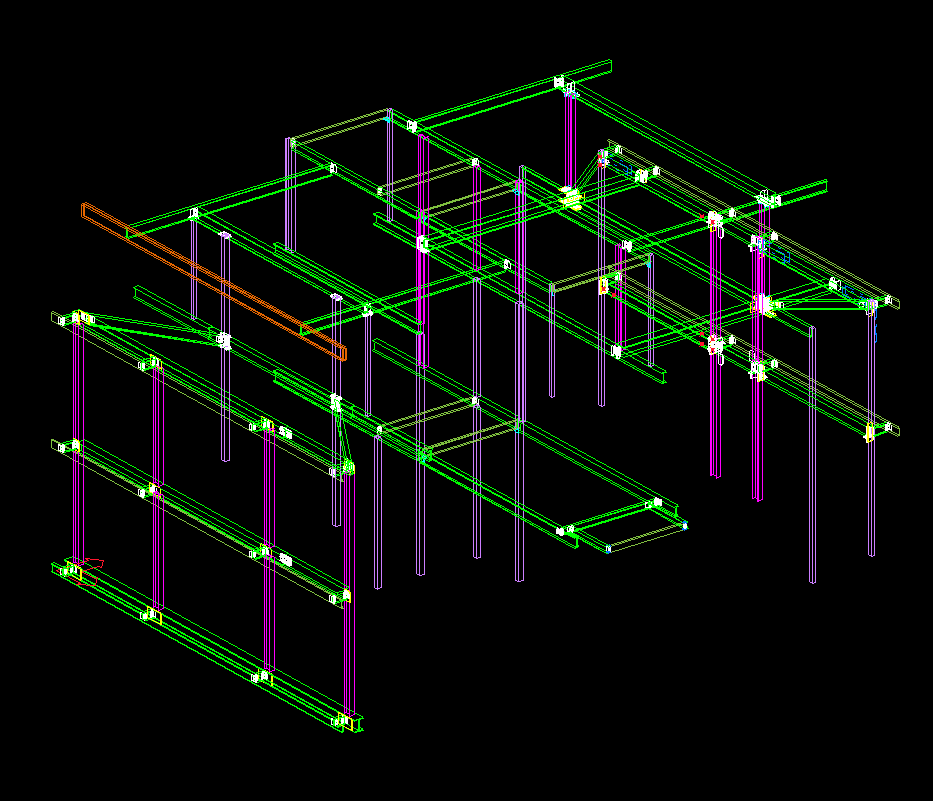

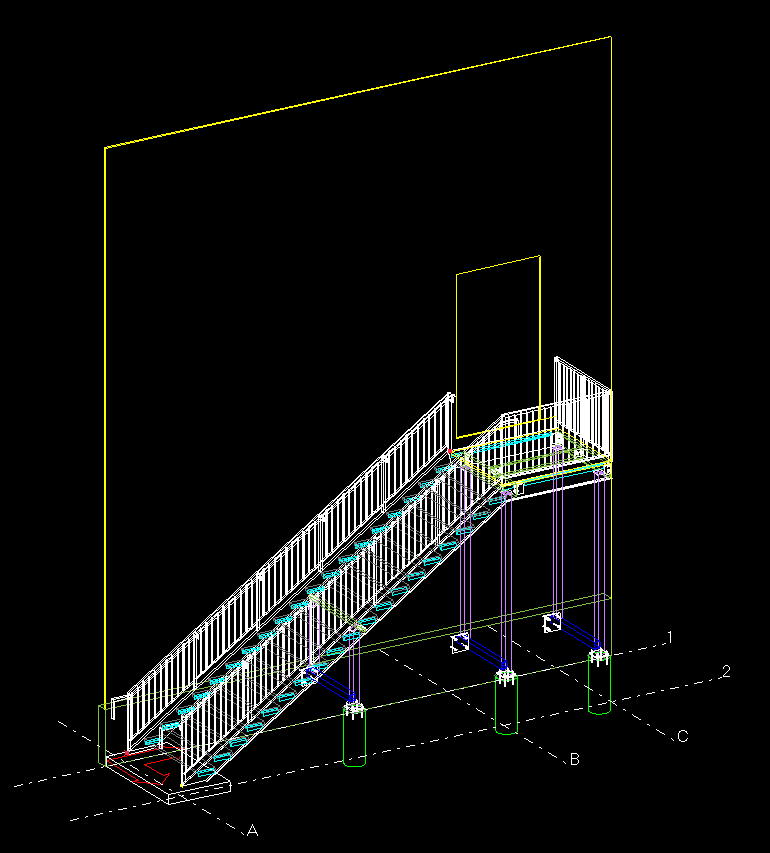

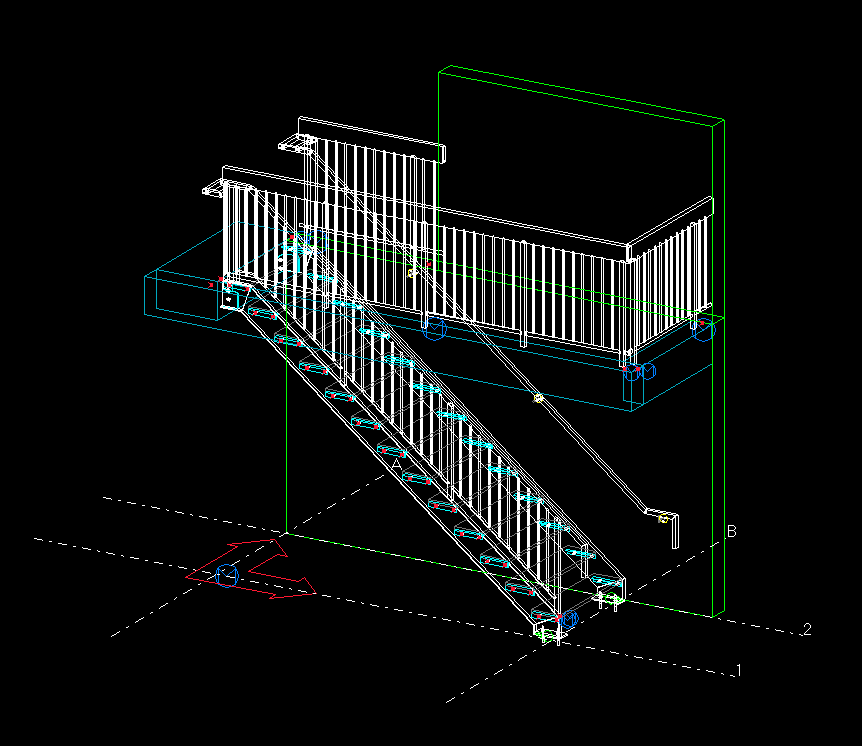

Steel detailing involves creating detailed plans, drawings, and other documentation for the manufacturing and construction of steel frameworks. The primary goal of steel detailing is to ensure that every steel component fits together correctly and is installed accurately, ensuring the structural integrity and safety of the building.

Steel detailers create two main types of drawings:

Shop Drawings: These are detailed plans that provide information on the dimensions, specifications, and fabrication instructions for each steel component. They are used by steel fabricators to cut, shape, and weld the steel parts.

Erection Drawings: These drawings guide construction workers on how to assemble the steel components on the construction site. They include detailed information on the placement of each steel piece, the order of assembly, and the connections between components.

The Importance of Steel Detailing

Ensures Structural Integrity

Accurate steel detailing is crucial for the safety and stability of any structure. Any errors or inaccuracies in the detailing process can lead to construction delays, increased costs, and potentially catastrophic structural failures. By providing precise and detailed plans, steel detailing ensures that all components are fabricated and installed correctly, maintaining the integrity of the structure.

Facilitates Efficient Construction

Detailed and accurate drawings streamline the construction process. They provide a clear roadmap for fabricators and constructors, reducing the likelihood of errors and rework. This efficiency not only saves time but also reduces costs, making the project more economical.

Enhances Collaboration

Steel detailing serves as a bridge between architects, engineers, and construction professionals. It translates the architect's vision and the engineer's design into a practical plan that can be followed on the construction site. This collaboration is essential for the successful completion of complex construction projects.

The Steel Detailing Process

The steel detailing process involves several key steps:

1. Reviewing Architectural and Structural Plans

The process begins with a thorough review of the architectural and structural plans. Steel detailers study these plans to understand the design requirements and identify any potential issues or conflicts.

2. Developing Preliminary Drawings

Based on the initial review, steel detailers create preliminary drawings that outline the general layout of the steel framework. These drawings are reviewed and approved by architects and engineers before moving on to detailed planning.

3. Creating Detailed Drawings

Once the preliminary drawings are approved, detailers create detailed shop and erection drawings. These drawings include precise measurements, material specifications, and detailed instructions for fabrication and construction.

4. Review and Quality Assurance

The detailed drawings undergo a rigorous review and quality assurance process. This ensures that all details are accurate and comply with industry standards and project specifications.

5. Final Approval and Distribution

After the drawings pass the quality assurance check, they are submitted for final approval by the project engineers and architects. Once approved, the drawings are distributed to fabricators and constructors for implementation.

Technologies Transforming Steel Detailing

The field of steel detailing has evolved significantly with advancements in technology. Here are some of the key technologies shaping its future:

Building Information Modeling (BIM)

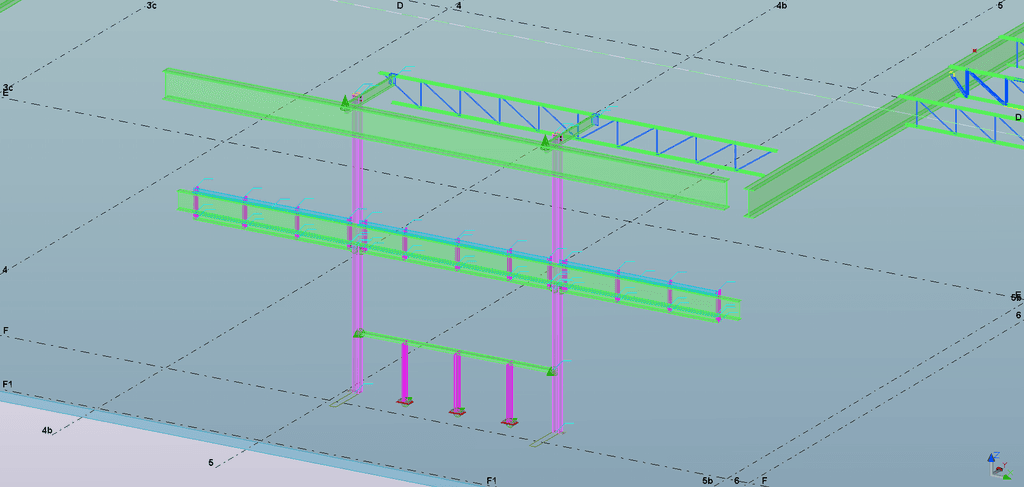

BIM is a digital representation of the physical and functional characteristics of a building. It allows for the creation of detailed 3D models that can be used to plan, design, construct, and manage buildings. BIM enhances the steel detailing process by providing a comprehensive view of the project, facilitating better coordination and reducing errors.

Computer-Aided Design (CAD) Software

CAD software has revolutionized steel detailing by enabling the creation of precise and detailed drawings digitally. Software like AutoCAD and Tekla Structures allows detailers to create 2D and 3D models, making it easier to visualize and plan the steel framework.

Automation and Robotics

Automation and robotics are increasingly being used in steel detailing and fabrication. Automated systems can cut, weld, and assemble steel components with high precision, reducing the risk of errors and speeding up the construction process.

Cloud-Based Collaboration Tools

Cloud-based tools enable real-time collaboration and sharing of steel detailing drawings and models. This ensures that all project stakeholders have access to the latest information and can collaborate effectively, regardless of their location.

Conclusion

Steel detailing is an essential component of modern construction, providing the detailed plans and instructions needed to fabricate and assemble steel structures. It plays a critical role in ensuring the safety, efficiency, and success of construction projects. As technology continues to evolve, steel detailing is becoming more precise, efficient, and collaborative, paving the way for the construction of even more complex and innovative structures in the future.

Understanding the importance of steel detailing and the processes involved can provide valuable insights into the world of construction and the meticulous planning that goes into building the structures that shape our world. Whether you're a student, a professional in the field, or simply interested in construction, steel detailing offers a fascinating glimpse into the backbone of modern engineering and architecture.