Last Edited:

Jun 25, 2024

1. Understanding Shop Drawings

Shop drawings are detailed, technical drawings created by fabricators, manufacturers, and contractors to guide the production and assembly of structural elements. Unlike architectural or design drawings, shop drawings focus on the specifics of how components are fabricated and assembled.

Key Elements:

Dimensions and Tolerances: Precise measurements and allowable deviations are specified.

Material Specifications: Details of materials, such as type, grade, and size, are provided.

Fabrication Details: Information on cutting, welding, bolting, and other fabrication processes.

Assembly Instructions: Directions for assembling components, including connections and fasteners.

Quality Standards: Specifications that ensure components meet required quality and performance criteria.

2. Introduction to CSA S16.1

The CSA S16.1 standard, titled Design of Steel Structures, outlines the requirements for the design, fabrication, and erection of structural steel in buildings. It provides guidelines for ensuring structural integrity, safety, and compliance with national building codes.

Key Aspects of CSA S16.1:

Design Principles: Establishes design methodologies for steel structures, including load considerations and design strengths.

Material Requirements: Specifies acceptable materials and their properties, ensuring consistency and quality.

Fabrication Guidelines: Outlines procedures for fabricating structural components, including cutting, welding, and bolting.

Erection Procedures: Provides guidelines for safely erecting steel structures, including stability and bracing requirements.

Quality Control: Emphasizes the importance of inspection and testing to maintain high standards.

3. Components of CSA S16.1-Compliant Shop Drawings

Creating shop drawings that comply with CSA S16.1 involves attention to detail and adherence to the standard’s requirements. Key components include:

1. Accurate Dimensions and Details

Exact Measurements: Ensure that all dimensions are accurate and clearly marked, with no room for ambiguity.

Detailing of Components: Each component should be detailed with precise dimensions, including length, width, height, and thickness.

Tolerances: Specify acceptable tolerances for deviations in dimensions to accommodate manufacturing variability.

2. Material Specifications

Material Grades: Clearly indicate the grade of steel to be used, as specified in CSA S16.1.

Properties: Include material properties such as tensile strength and yield strength to ensure compliance with structural requirements.

Certificates: Provide certification that materials meet CSA S16.1 standards.

3. Fabrication Instructions

Cutting and Shaping: Provide detailed instructions for cutting and shaping components, including dimensions and angles.

Welding Specifications: Include weld types, sizes, and positions, as well as welding procedures that comply with CSA S16.1.

Bolting Details: Specify bolt sizes, types, and installation procedures to ensure proper connections.

4. Assembly and Erection Guidelines

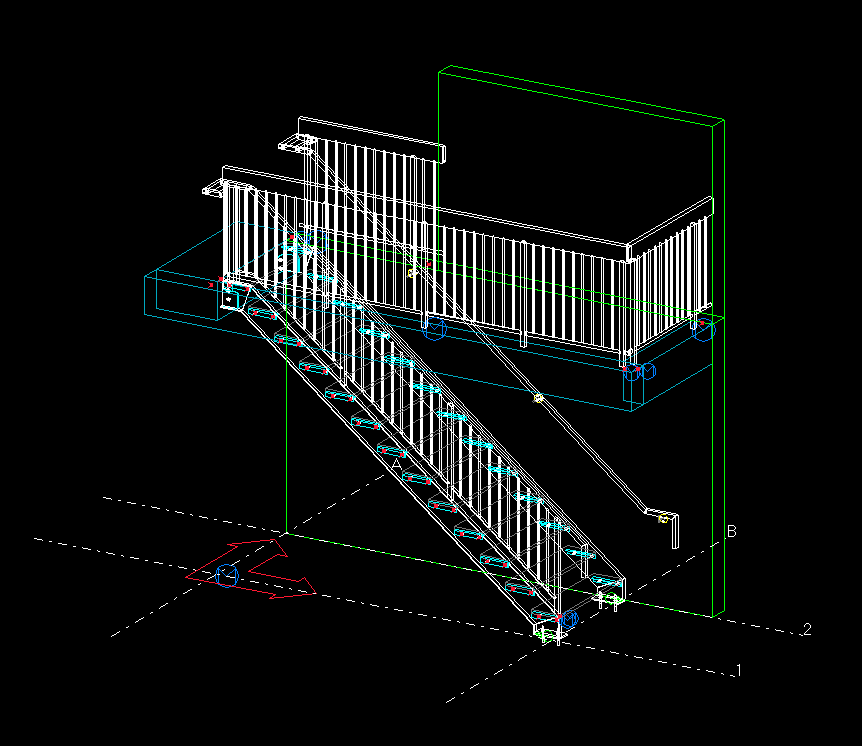

Assembly Sequences: Outline the steps for assembling components, ensuring they are assembled in the correct order.

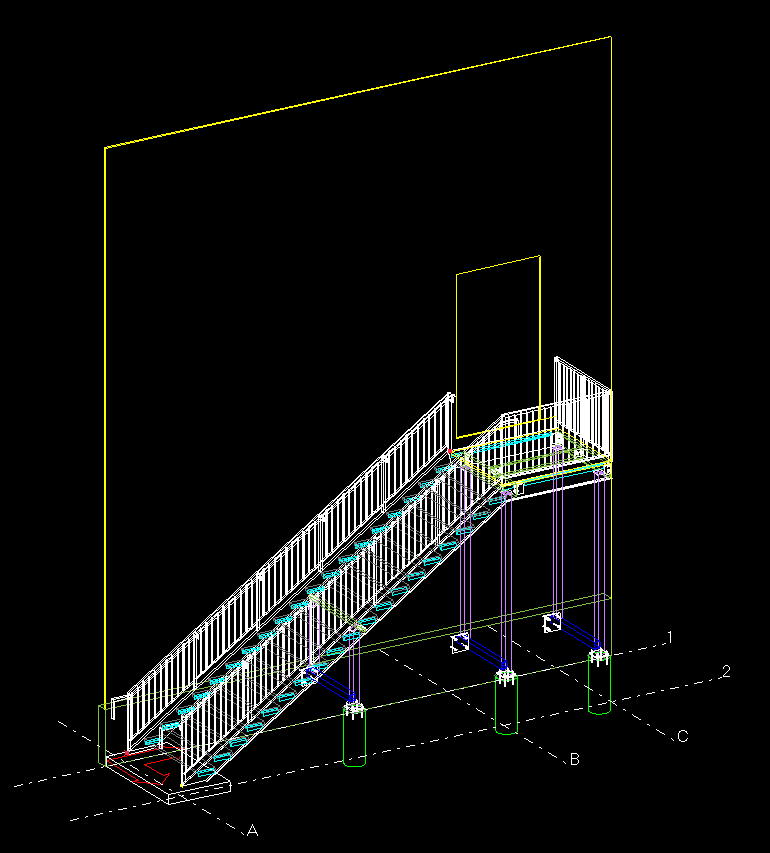

Connection Details: Provide detailed drawings of connections, including bolted and welded joints, ensuring they meet CSA S16.1 requirements.

Safety and Stability: Include guidelines for ensuring the stability and safety of the structure during erection.

5. Quality Assurance

Inspection Procedures: Detail the inspection and testing procedures required to verify compliance with CSA S16.1.

Documentation: Maintain thorough documentation of all inspections, tests, and quality checks.

Corrective Actions: Outline procedures for addressing any discrepancies or defects found during inspection.

4. Best Practices for Creating CSA S16.1-Compliant Shop Drawings

Adhering to CSA S16.1 standards requires a combination of technical knowledge and attention to detail. Here are some best practices to follow:

1. Collaboration and Communication

Work Closely with Designers: Ensure close collaboration with architects and engineers to understand design intent and requirements.

Communicate Clearly: Maintain open lines of communication with all stakeholders to clarify any questions or issues.

2. Use Advanced Software

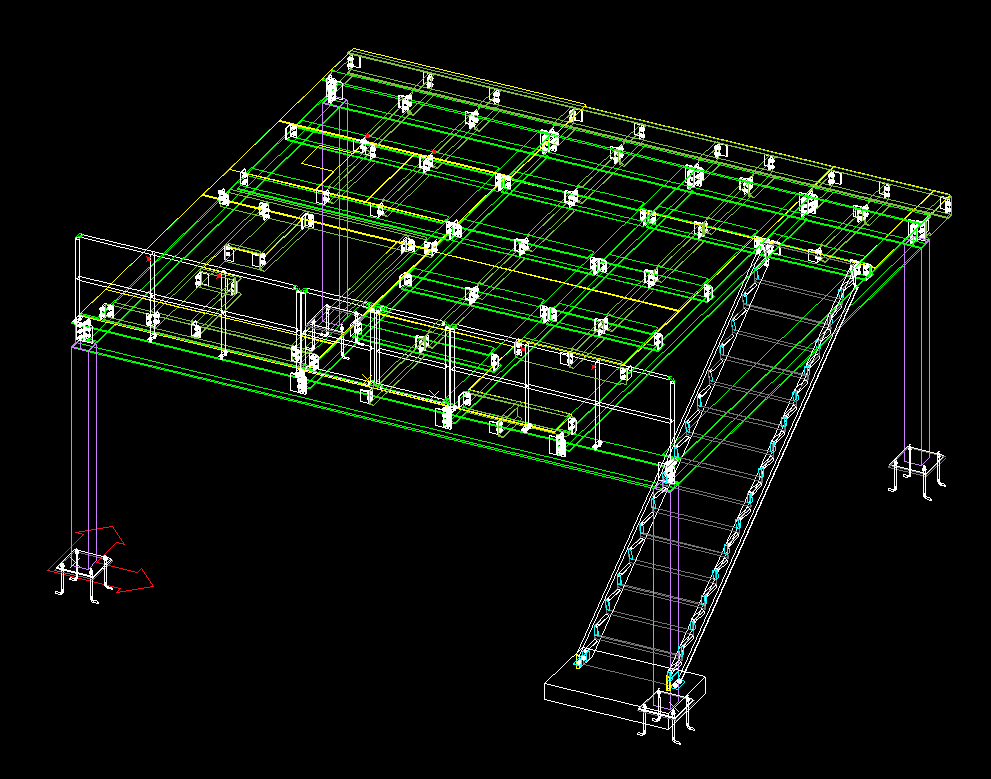

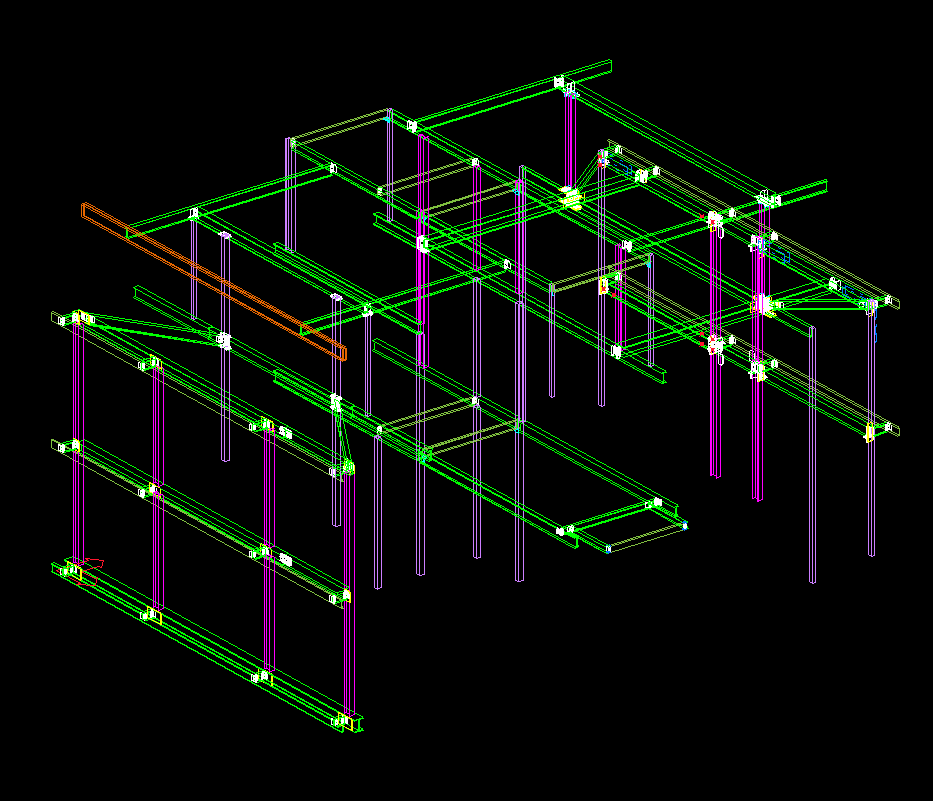

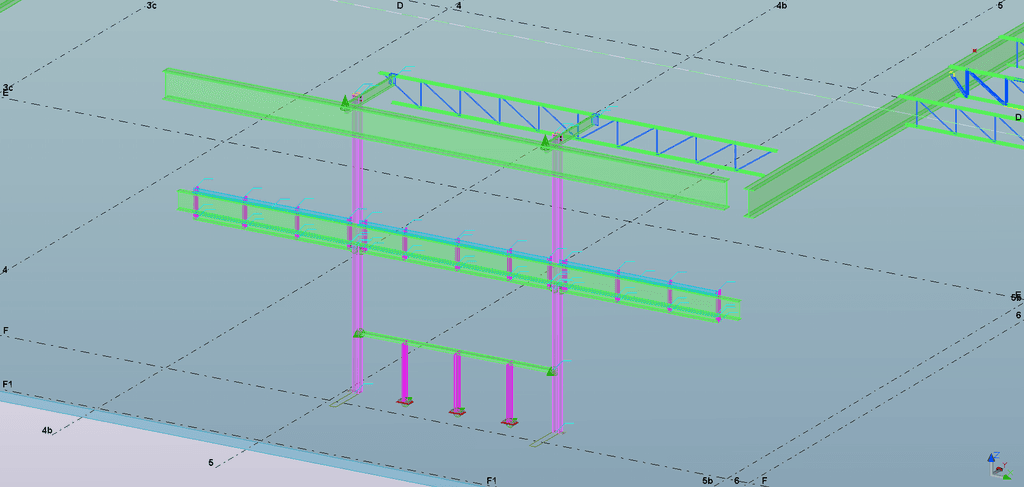

CAD/BIM Tools: Utilize advanced software tools for creating detailed and accurate shop drawings.

Software Integration: Ensure your software is compatible with other tools used in the project to facilitate smooth data exchange.

3. Follow a Checklist

Standard Compliance: Use a checklist to verify that all aspects of the shop drawings comply with CSA S16.1.

Quality Control: Include quality control checks in your process to identify and correct any errors or omissions.

4. Continuous Learning and Improvement

Stay Updated: Keep up-to-date with any changes or updates to CSA S16.1 and other relevant standards.

Training and Development: Invest in training and professional development for your team to maintain high standards of practice.

Conclusion

Shop drawings are a critical component of the construction process, serving as the blueprint for fabricating and assembling structural elements. Adhering to the CSA S16.1 standard ensures that these drawings meet the highest standards of accuracy, quality, and safety. By following best practices and leveraging advanced tools and technologies, you can create shop drawings that not only comply with standards but also contribute to the success and safety of your construction projects.

References

Canadian Standards Association. (2024). CSA S16.1-19: Design of Steel Structures. Retrieved from CSA Group

Steel Construction New Zealand. (2024). Understanding Shop Drawings: Best Practices and Standards. Retrieved from SCNZ

Steel Structures Education Foundation. (2024). Guide to Steel Shop Drawings. Retrieved from SSEF

Tekla. (2024). Creating Accurate Shop Drawings in Tekla Structures. Retrieved from Tekla

Canadian Institute of Steel Construction. (2024). Best Practices for Shop Drawings. Retrieved from CISC

Canadian Society for Civil Engineering. (2024). Compliance with CSA Standards in Structural Steel Fabrication. Retrieved from CSCE

Building Canada. (2024). The Role of Shop Drawings in Construction Projects. Retrieved from Building Canada

Structural Engineers Association of British Columbia. (2024). Structural Detailing and Shop Drawing Standards. Retrieved from SEABC

By adhering to these guidelines and leveraging the CSA S16.1 standard, you can ensure that your shop drawings meet the highest levels of quality and compliance, contributing to the success of your construction projects.